Canal Lachine Bridge – Montréal, Canada

Client

- Ministère des Transports du Québec (MTQ)

Project Value

$80-$100 Million

Market

Transportation

Services

Design And Urban Planning, Engineering, Program/Construction Management (PM/CM)

The new Canal Lachine Bridge in Montréal, Canada, designed by Parsons, is the first curved extradosed bridge with multiple steel box girders and a composite concrete deck. The clearance envelope for the canal, in combination with the given Profile-Grade-Line (PGL) and the meaningful crossfall of 6%, were decisive for the superstructure concept, which had to bridge an 88-m (289-feet) long main span with an only 2-m (6.6-feet) deep girder along the inner curve. This requirement corresponds to a slenderness of 44 (span-over-depth ratio), which is remarkable for traditional beam superstructure types.

Innovation in Bridge Design and Construction

The reference concept was anticipating a cable-stayed bridge with two large and torsionally stiff steel box girders to satisfy the performance requirements. Hereby, a wide-cantilevering deck was selected to guarantee the 6% crossfall and maintain the clearance envelope below. In addition, a lightweight orthotropic steel deck and a tower separated from the superstructure were proposed.

During the bid phase of this Design-Build Project, the orthotropic deck was found to be more expensive and challenging to design, fabricate, and construct than a traditional concrete deck. Therefore, it was decided to investigate the concrete deck option. The heavier concrete deck increased the problems for the slender girders from a demand and deflection perspective. The team realized that simple steel plate girders could not meet the design objectives regarding constant girder depth and slenderness.

Overcoming Challenges

Another challenge the team overcame was live load deflections. The slender girders along the inner curve would have significantly deflected and twisted the cross-section if torsional stiff box girders were omitted. However, the two box girders proposed by the reference concept were costly and too large to be shipped. For fabrication and construction reasons, it was decided to investigate multiple small box girders tied together to form a mega steel grillage system that provides simplicity, repetition, structural redundancy, and stiffness (see Figure 1).

Parsons’ engineers took advantage of the fact that in a curved superstructure and hyperstatic structural system, the lack of vertical bending stiffness can be partially compensated by providing torsional stiffness and capacity. To realize this effect, take your arm and bend it at a 90-degree angle. A bending moment at your wrist turns fully into a torsional moment at your shoulder and vice versa. Structural engineers know that the forces (moments and shear) in hyperstatic structural systems depend on the bending stiffness distribution in the system. This is no different for bending and torsion in a curved hyperstatic system where the torsional stiffness of box girders directly effects the bending moments and helps to redistribute high local demands in one box girder if multiple coupled box girders are used. This effect was the solution for the Canal Lachine Bridge because it allowed a concrete deck without compromising the performance criteria and the architectural vision which follows the Millau Viaduct in France.

Figure 1: Cross section of the bridge’s superstructure with the tower support beam and the tower base

The superstructure of the Canal Lachine Bridge utilizes the bending and torsional stiffness of six coupled box girders (numbered as A, B, C, D, E, and F in Figure 2) to achieve redundancy, strength, and stiffness for vertical loads. For instance, for the governing live load constellation, causing the largest superstructure deflection for the slenderest box girder (girder A in Figure 2), we found a maximum deflection of only 88 mm (3.5 inches) or a deflection-over-span ratio of 1/1,000. This remarkable value was achieved without compromising the superstructure’s horizontal flexibility required for temperature change and seismic performance. The principle of structural isolation via friction-pendulum bearings permitted cost-efficient substructure and foundation solutions that fully satisfied architectural as well as service, ultimate, and seismic design aspects.

An Innovative And Complex Design

Structurally complex bridges such as the Canal Lachine Bridge mandate an excellent understanding of primary load paths and the flow of forces. To understand the interaction of vertical bending and torsion in a box girder, Parsons’ engineers developed a model that visualizes the flow of forces in curved box girders and computes the cross-frame forces without the use of a complex refined Finite-Element model that captures all aspects of the box girder. From the six forces found for each box girder in the global spine model (axial force, strong and weak axis bending, strong and weak axis shear, and torsion), stresses in box girder flanges and webs were computed using the properties of relevant cross sections and the Mises linear stress superposition method.

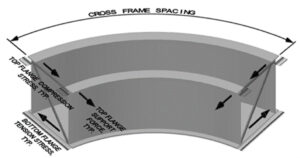

Figure 2: Flange support forces provided by the cross frames inside the box girder

However, the axial stresses (due to vertical bending) in the curved flanges of a girder, generate deviation forces acting in opposite radial directions on top and bottom flanges. Those deviation forces cause secondary bending stresses in the flanges and must be considered when computing the extreme stresses at the flange edges. The flanges are laterally supported by the cross frames. Depending on the cross-frame spacing (unsupported length), the axial flange stresses, and the radius of the box girder, the secondary flange bending stresses and flange lateral support reactions can be quantified (see Figure 2).

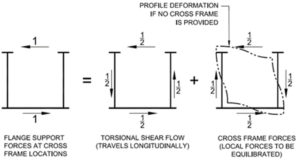

With the lateral top flange and bottom flange support forces known, the cross frame forces can be derived by hand with simple strut-and-tie models after the flange lateral support reactions are replaced by two individual models: one that produces a constant torsional shear flow in the box girder (which travels in longitudinal girder direction) and a second one that clearly shows the local forces which are balanced by the cross frame members (see Figure 3). In other words, Figures 2 and 3 explain how a vertical bending moment is converted into a torsional moment when following the forces along the longitudinal direction of a curved box girder. This allowed the team to optimize cross frame forces and spacing.

But the innovation did not stop here: Composite action between the concrete deck and the coupled box girders only accounted for superimposed dead load and transitory loads. This innovative design philosophy for cable-supported bridges enabled slender full-depth precast deck panels without post-tensioning. More importantly, it allows future deck panel replacements without rebuilding the steel superstructure. This important design feature cannot be found in traditional cable-stayed bridges where the concrete deck is designed to be an integral part of the primary load path for dead load.

Figure 3: Models to visualize torsion and distortion demands

The tower of the Canal Lachine Bridge is a free-standing mast in radial bridge direction. For stability reasons, a fully restrained tower base is essential. The reference concept showed a tower that had its foundation and was separate from the superstructure. However, this separation of tower and superstructure (but connected thru stays) has significant disadvantages in a seismic event when superstructure movements relative to the tower occur. To address this significant problem for the tower and its foundation, the team framed it into the superstructure so that both systems (the girder and stay system) become one fully integrated extradosed superstructure system. This modified superstructure type is in complete isolation from the substructure to improve the seismic performance of the bridge and reduce the design demands for the substructure and the bridge’s foundations.

Our Approach

The Canal Lachine Bridge is an example of an innovative design approach that combines the idea of a curved extradosed bridge with a composite steel grillage system using multiple small steel box girders. In this context, strut-and-tie models were applied to visualize the shear flow in torsionally stiff box girders and to develop a method to compute the cross-frame forces by hand. This reduced the complexity of the global bridge model and maintained the simplicity needed for the verification of global structural performance and engineering judgment. The design is evidence that the application of the beam theory for multiple coupled box girders, in combination with the design principles of hyperstatic structural systems, can deliver exceptional results regarding slenderness, stiffness, structural redundancy, constructability, and cost-efficiency.

Awards

For its innovation, the Canal Lachine Bridge has been awarded the prestigious 2022 ENR Best Global Project Award in the Bridge and Tunnel Category. It is nominated for the 2022 ENR Project of the Year Award as well.

Learn More

With more than 70 years of experience applying innovative solutions to some of the largest, most complex bridge projects in the world, our experts are dedicated to overcoming the toughest challenges to help our customers move safely over any obstacle. We design and build bridges that enrich skylines and provide efficient transportation. Our portfolio includes more than 4,500 crossings around the world, including landmark projects that carry pedestrians, roads, railways, and pipelines. Learn more about our bridge expertise.