TRS Group

Thermal Remediation Services Of VOCs, SVOCs, & PFAS

TRS Group (TRS), a Parsons company, provides thermal remediation technologies for the volatilization of organic contaminants from soil, bedrock, and groundwater in North America, South America, and Europe.

What Is Thermal Remediation?

Thermal remediation involves heating the subsurface (or a soil pile) to volatilize organic compounds, including chlorinated solvents, petroleum hydrocarbons and PFAS.

The most deployed technologies in thermal remediation are electrical resistance heating (ERH) and thermal conduction heating (TCH). The systems include integral vapor capture and treatment at the surface. The technologies are remarkably robust, work in tight matrices, including clay and bedrock, and typically achieve concentration reductions exceeding 99.9%.

How Does Thermal Remediation Work?

TRS heats the subsurface (or stockpiled soil) to vaporize the contaminants, which we capture, extract and treat with above ground systems (usually granular activated charcoal). Interestingly, our methods first remediate light and dense non-aqueous phase liquids (LNAPL and DNAPL, respectively). TRS has completed more than 200 thermal remediation projects, primarily for source zone removal.

We have applied our remedial solutions (in situ and ex situ) to treat chlorinated solvents, petroleum hydrocarbons, and PFAS. Typical contaminant reductions exceed 99.9%. Our patented technologies are so robust that we often guarantee results.

Please fill out the form below to have our experts evaluate your site and provide our technical approach and pricing.

Comparing Different Types Of Thermal Remediation

| Technology | Soil Types | Contaminants | Temperature |

|---|---|---|---|

| Thermal conduction heating (TCH) | All types and bedrock | VOCs in all matrices SVOCs and PFAS in vadose zone or ex situ | Up to 600°C in vadose zone or ex situ |

| Electrical resistance heating (ERH) | All types and bedrock | VOCs in all matrices | Boiling point of water |

| Steam enhanced extraction (SEE) | Sand and gravel | Primarily for LNAPL removal | Boiling point of water |

Thermal Conduction Heating (TCH)

- Soil Type: All types and bedrock

- Contaminants: VOCs in all matrices SVOCs and PFAS in vadose zone or ex situ

- Temperature: Up to 600°C in vadose zone or ex situ

Electrical Resistance Heating (ERH)

- Soil Type: All types and bedrock

- Contaminants: VOCs in all matrices

- Temperature: Boiling point of water

Steam Enhanced Extraction (SEE)

- Soil Type: Sand and gravel

- Contaminants: Primarily for LNAPL removal

- Temperature: Boiling point of water

Featured Projects and Highlights

PFAS Solutions

Per- And Polyfluoroalkyl Substances The legal and regulatory landscape for PFAS is in flux and continues to evolve. However, significant progress has been made in the technical understanding of PFAS, […]

Read MoreParsons Acquires TRS Group, Inc.

Acquisition strategically enhances Parsons’ cross-segment environmental remediation capabilities CHANTILLY, VA (February 4, 2025) – Parsons Corporation (NYSE: PSN) announced today that it has acquired TRS Group, Inc. (TRS), an environmental […]

Read MorePerfluorAd™: A Breakthrough For AFFF Decontamination In Fire Suppression

Explore how aqueous film forming foams work in fixed fire suppression systems, the health risks of PFAS, and how PerfluorAd™ can help.

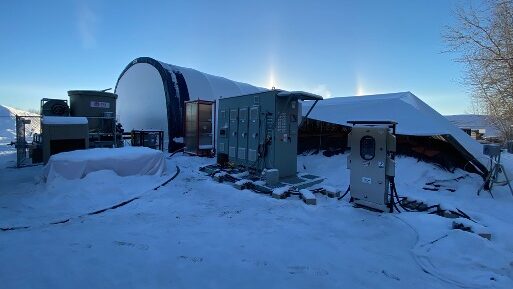

Read MoreThermal Desorption Of PFAS In Soil Remediation — Anchorage, Alaska

In October 2024, TRS Group (TRS) completed its third and largest thermal desorption of per- and polyfluoroalkyl substances (PFAS) in soil remediation project at Joint Base Elmendorf-Richardson (JBER) in Anchorage, […]

Read MorePerfluorAd™

Explore PerfluorAd technology for effective PFAS remediation and thermal soil treatment, as well as AFFF cleanout.

Read MoreElectrical Resistance Heating Remediation In Europe During Covid-19 Pandemic

We completed the first electrical resistance heating (ERH) project in Germany in May 2021. The site at US Army Garrison (USAG) Wiesbaden was a former maintenance area near the airport […]

Read MoreTRS Group Embraces Guarantees

May 13, 2021 We have such confidence in our robust heating technologies and our employes, we have offered guarantees on more than 75% of our projects. Further, our guarantees have […]

Read MoreCalibrating Thermal Remediation Models

As we offer electrical resistance heating, steam enhanced extraction, and thermal conduction heating services, it is crucial that we provide our clients with the most cost-effective thermal solution that meets […]

Read MoreERH In An Active Facility

The Arrowhead Associates, Inc./Scovill Corp. Superfund Site (the Site) is in Virginia’s Northern Neck region between the Rappahannock and Potomac Rivers. Historical manufacturing activities, including degreasing and electroplating, resulted in […]

Read MoreClient Testimonials

"I appreciate their dedication to client service, their hard work, commitment to quality, going above and beyond, giving it their all, solving problems in a quality way, and excellent communication skills. I really appreciate their ability to solve problems without needless change orders. They are rock stars."

Mike Palmer, Project Coordinator

de maximis

“Working with TRS on this project was one of the highlights of my career. Coming into the project, I was excited knowing that it would be a combined remedy with a few site-specific nuances. From the onset of construction, to operation, to thermal destruction of the TCE source area, to final decommissioning of the equipment, the TRS team was exceptional at communicating with me what data they needed for successful implementation of their thermal system. The client was ecstatic about the results that we achieved."

Scott Connors, Senior Geologist

Wilcox Environmental Engineering

“I tend to be skeptical of most in situ remediation technologies. Just because a concept proves effective in a lab, doesn’t mean it will always translate to your site. There’s one exception. After using in situ thermal remediation on one of our projects, I’m a believer. ISTR works. If you can deliver the heat, you can extract your source.”

Jonathan Shuptar P.G., Geologist

V3 Companies

"As a member of the Department of Defense’s ESTCP review committee, I evaluated, and ultimately approved, TRS Group’s proposal to demonstrate their ex-situ thermal desorption technology for PFAS-impacted soils at Eielson Air Force Base in Fairbanks, Alaska. Not only did TRS achieve the goal of reaching an average soil pile temperature of 350 degrees Celsius, but TRS, at its own expense, also kept the system running and reached an average temperature of 414 degrees. The TRS project and engineering professionals were dedicated, worked diligently, and communicated well throughout the project. Subsequently, as a reviewer for DOD’s Defense Innovation Unit, I evaluated, and ultimately approved, TRS’s funding request for a similar, but larger, ex-situ soil project in Anchorage, Alaska, to compare the cost-efficiency of TRS’s thermal desorption technology to similar technologies for PFAS-impacted soil."

“TRS closely collaborated with our team and was a true partner that shared real project risk. Throughout the complex implementation of the project, TRS unwaveringly met the needs and addressed the concerns of multiple stakeholders, including a major railroad, community organization, US Army Corps of Engineers, US Air Force, US EPA and utilities. TRS’s professionalism, technical proficiency and leadership yielded a successful outcome lauded by our Government clients and resulted in ‘Exceptional’ Contractor Performance Assessment Reporting System (CPARS) ratings for three years in all categories.”

Ken Cottrell, Principal

HydroGeoLogic

“Environmental Restoration has enjoyed partnering with TRS on thermal remediation projects since 2017. TRS is a knowledgeable and professional partner whose technical expertise has been invaluable in remediating challenging Superfund Sites.”

“TRS Group came on to our project at a critical time and was able to take on contractual performance risks that were requirements of the project. Due to the financial stability of their firm, TRS was also able to secure the necessary payment and performance bonding to provide further assurances to Ramboll and our client. Further, TRS held the patents to thermal conductive heating technology that ensured their ability to fully execute the project. They provided and met an aggressive schedule that was required by the client all while working through COVID with multiple out-of-state drilling subcontractors. Performance of the thermal conduction heating system exceeded expectations. Performance was confirmed through soil temperature and energy monitoring as well as vapor-based asymptote tracking. Once these lines of evidence were met, soil sampling was performed and confirmed that the soil goals had been exceeded by an order of magnitude. As challenges presented themselves, TRS took a collaborative approach with Ramboll and our client to ensure the project moved forward in a mutually beneficial, productive way.”

Employee Spotlights

Our employee spotlights showcase the unique expertise and experiences that shape our team. From varied career paths to specialized skills, each profile offers a glimpse into the talent and perspectives driving our projects.

Employee Spotlight: Michelle Nanista

Learn more about Michelle Nanista, Managing Principal Engineer at TRS, A Parsons Company. Position: Managing Principal EngineerLocation: Pacific, MissouriTRS Employee-Owner Year Started: 2008Specialties: Pricing development, cost support, technology selection and […]

Read MoreEmployee Spotlight: Matt Pockette

Learn more about Matt Pockette, Corporate Safety Manager at TRS, A Parsons Company. Title: Corporate Safety ManagerYears at TRS: 1.5 TRS: Please tell us a bit about your background and […]

Read MoreEmployee Spotlight: Nathan Fehrman

Learn more about Nathan Fehrman, System Specialist II Engineer at TRS, A Parsons Company. Title: System Specialist IILocation: TennesseeYear started at TRS: 2019Education: Bachelor of Science in Economics and Political Science from […]

Read MoreEmployee Spotlight: Emily Crownover

Get to know Emily Crownover, a key player at TRS, and her impressive background in bioengineering and system optimization.

Read MoreEmployee Spotlight: Susan Avritt

Meet Susan Avritt from TRS. Learn about her transition from environmental consulting to project management and her specialties.

Read MoreEmployee Spotlight: Will Pack

Meet Will Pack, a Construction Technician at TRS, and learn about his unique experiences and skills in plumbing and site management.

Read MoreEmployee Spotlight: Patrick Joyce

Meet Patrick Joyce, Project Manager at TRS, and discover his insights on environmental remediation techniques and site walks.

Read More